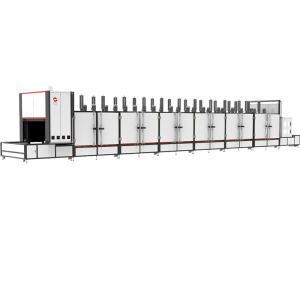

Double -Door Vertical Hot Air Oven

Drying of Single/Double-sided PCB printing, Legend Printing in Multi-Layer Plates, Pre&Post-Bake of Solder Mask, Pre-Bake of Plugging, Ink, HASL.

1,Adopt patent heating system, energy saving 30%

2,Adopt high-speed circulating fan, equipped with patented wind wheel to transport wind

3,Adopt industrial computer control system

4,Use imported 100-level high-efficiency filter to filter circulating air

5,With 2 sets of over-temperature indication and alarm function

6,The inner box is made of 1.0mm stainless steel plate, and the outer box is made of 1.2mm thick A3 iron plate;

7, Insulation material: 100K environmentally friendly high-temperature cotton is used, and the insulation thickness is 100mm;

8,Door edge sealing: It is tightly sealed with high temperature resistant silica gel.

9,Accept customer customization.

PLC: MITSUBISHI

Motor: TaiWan

Solid state: AUTONICS

Touch screen: weinview

Communication: MITSUBISHI

Thermostat: RKC

Maximum processing size: 630 mm×730mm

Minimum processing size: 350mm×400mm

Board thickness range: 0.02-4.0mm

Temperature uniformity: ±2℃

Oven size: can be customized according to requirements

Baking method: high-speed circulating hot air

Function selection: can be divided into single-stage/multi-stage baking options

Temperature range: normal temperature -220℃

Exhaust air volume: 6-8m/s