Factory directly supply Diy Line Table Screen Printing Press - Automatic smart silk screen printing machine – Xinjinghui

Factory directly supply Diy Line Table Screen Printing Press - Automatic smart silk screen printing machine – Xinjinghui Detail:

PCB solder mask printer,pcb legends printer,glass silk screen printing,solar silk screen printing,pvc,movbile cover and so on

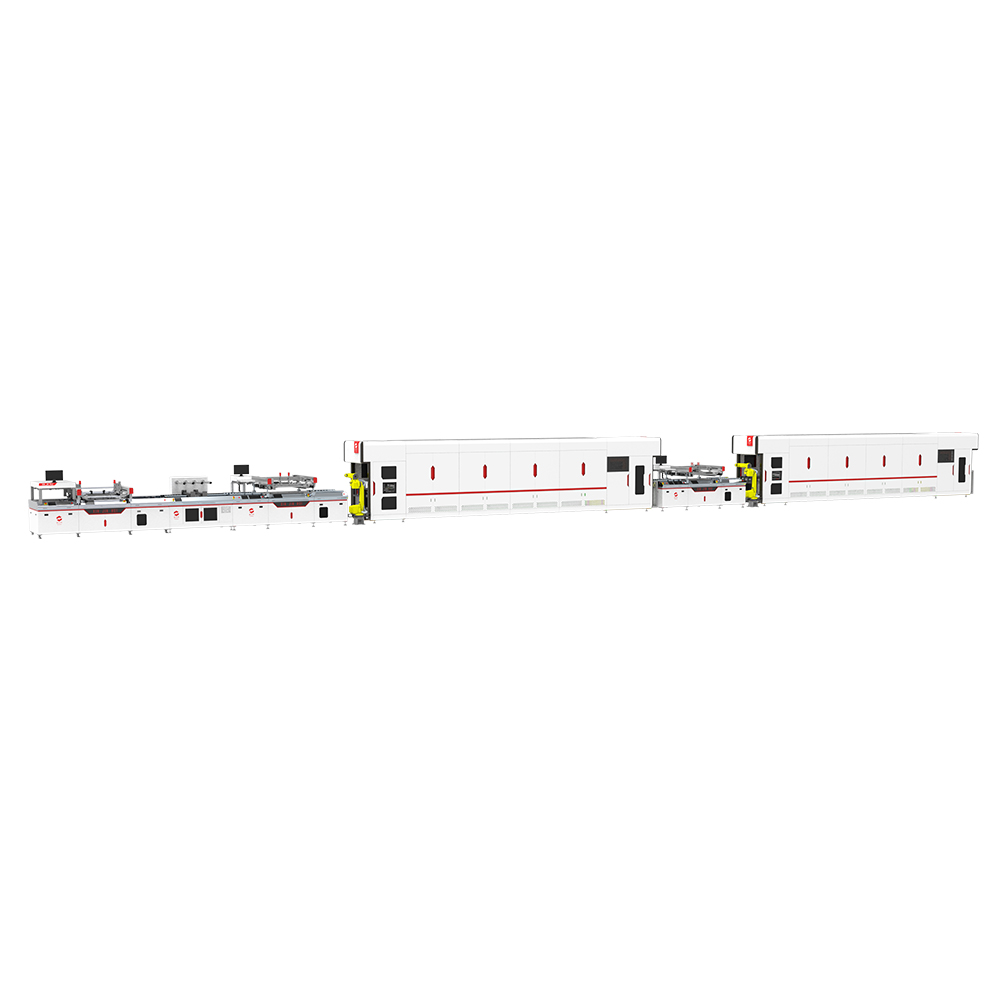

The whole machine is composed of a fully intelligent CCD system alignment section, printing section and material return section, with the left and right shuttle table in the middle to move the printed parts in series. Suitable for solder mask/character ink printing.

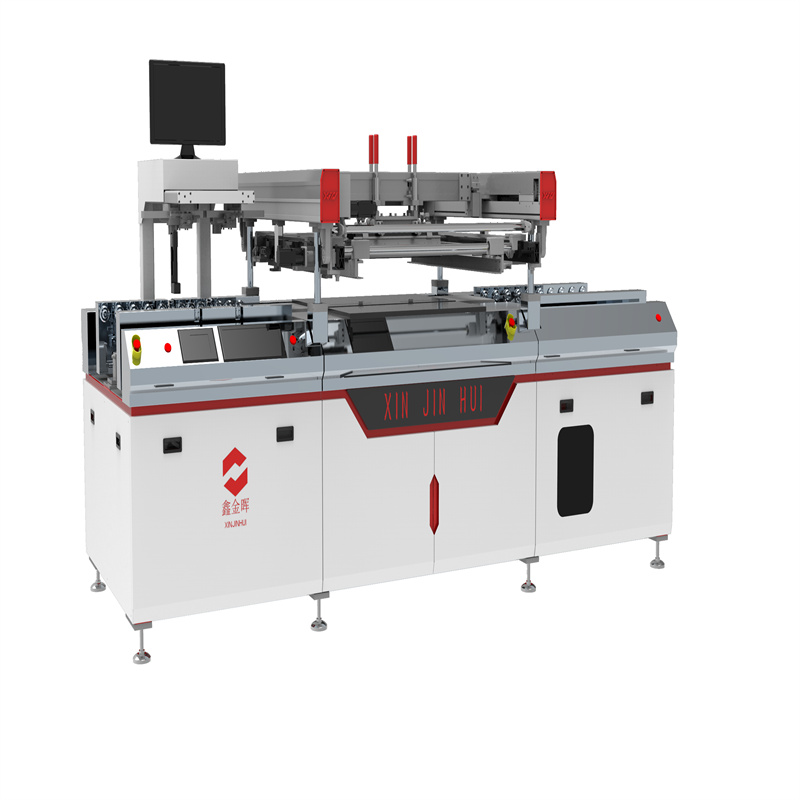

1,The feed positioning adopts a full-servo automatic plate matching system, and the positioning accuracy reaches the um level.

2,Servo motor drives printing and pneumatic off screen to realize synchronous off screen function and effectively prevent screen sticking. The servo motor drives the printing piece to move quickly and smoothly to ensure the accurate positioning of the printing piece.

3,Servo motor and precision guide rail guide ensure accurate positioning and longer service life. The vertical horizontal lifting structure of the printing frame ensures that the pressure of the scraper is balanced.

4,smart interface touch operation, easy to set, and automatic fault detection and troubleshooting display. The printing pressure and screen plate can be adjusted conveniently and accurately, and the angle of the scraper can be adjusted at will.

5,CCD image automatic alignment system, combined with left and right running platforms, enables faster operation and high alignment accuracy. The multi value processing of the image system is not limited by any graphics, and any graphics can be used as a target.

6, Discharge section

The discharge section is equipped with discharge conveying rollers to take the treadmill and bring it into the base plate, and bring it back to the conveyor.

The above design is based on the concept of “intelligent connection operation”, and with the horizontal conveyors in the front and rear sections, the input manpower can be greatly reduced and the production capacity can be increased.

Product detail pictures:

Related Product Guide:

Control the standard by the details, show the power by quality. Our firm has strived to establish a extremely efficient and stable employees crew and explored an effective excellent command method for Factory directly supply Diy Line Table Screen Printing Press - Automatic smart silk screen printing machine – Xinjinghui , The product will supply to all over the world, such as: Macedonia, Philadelphia, Tajikistan, Our products are widely recognized and trusted by users and can meet continuously changing of economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.