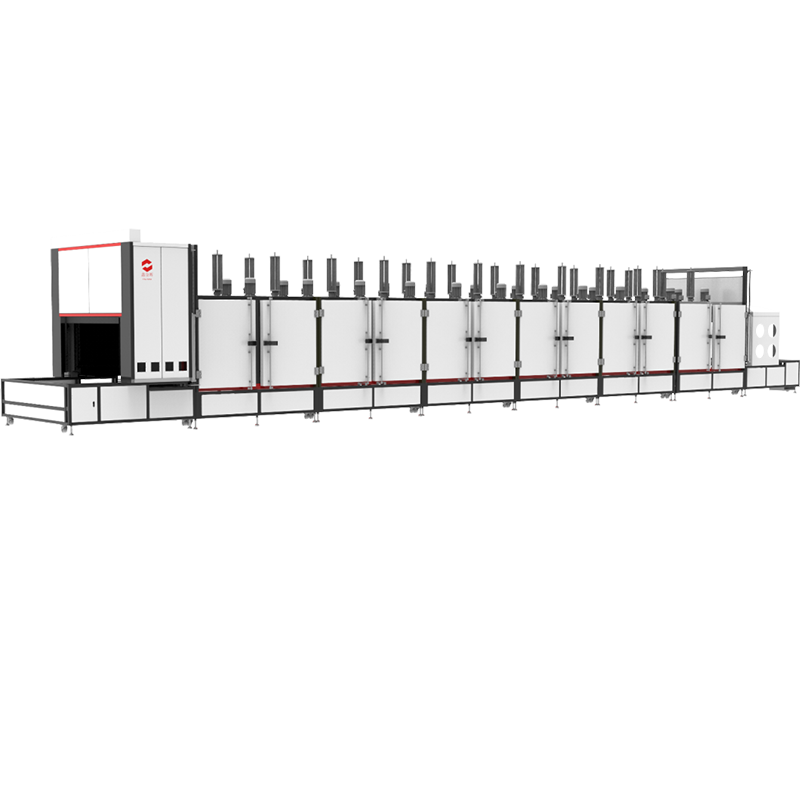

Factory made hot-sale Curing Machine Screen Printing - Fully Automatic Thin Sheets Solder Mask Printing Line – Xinjinghui

Factory made hot-sale Curing Machine Screen Printing - Fully Automatic Thin Sheets Solder Mask Printing Line – Xinjinghui Detail:

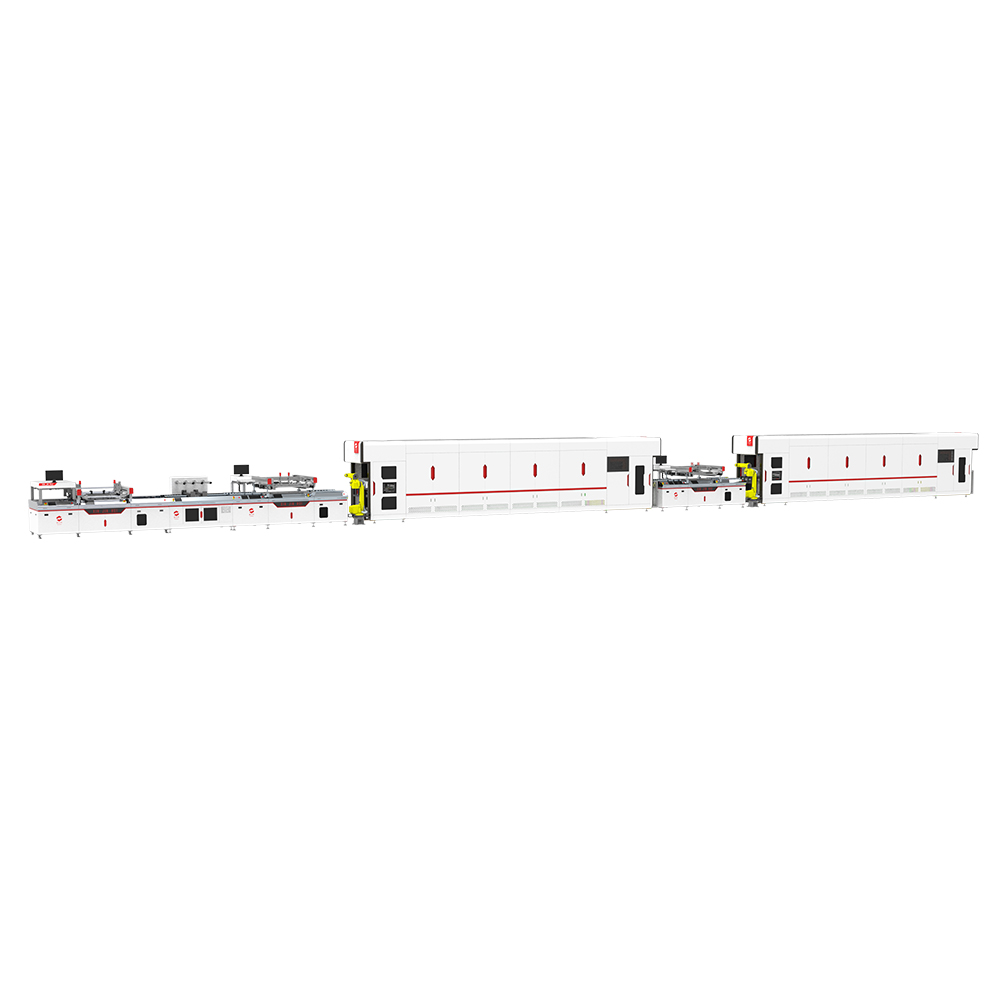

CCD alignment system is adopted, and the material number is switched in 3-5min

Compatible with the production of 0.4mm-3.0mm plates

The production capacity reaches 3-6pnl / min

Realize [digitalization], [parameterization] and [intelligence]

Manipulator loading and unloading to realize the whole line fully automatic

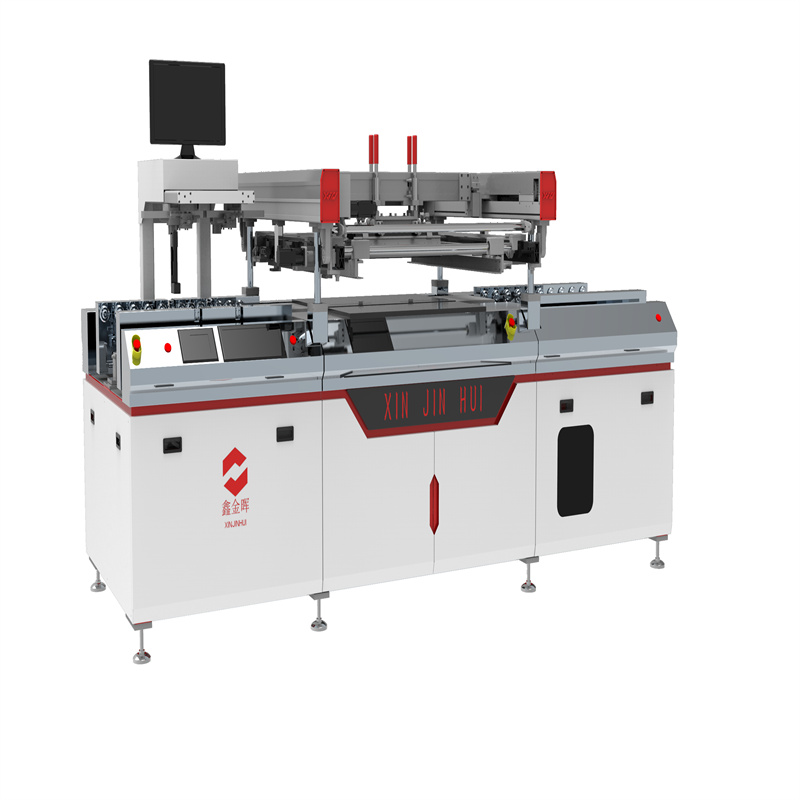

Visual Registration: 2 CCD cameras detect registration mark or hole on substrate rapidly, mathematically calculate position off-set amount providing to control system, X/Y servo transmission system drives registration table immediately to precise position.

Laser Point: CCD camera module is locked / unlocked by pneumatic control switch, fast displacement and manual fine adjusting front back / right left position, collocated with laser point projection for quick moving to target position.

Digital Control Screen Micro Adjustment: replace manual three-point micro adjustment, which is unable to adjust precisely obtaining the requested position, digitalized control compensation attains quick precise efficiency.

Buffer Stacker: when B side screen printer stops for screen cleaning, A side incoming after printing, temporary stack into buffer stacked to avoid influence production efficiency.

Automatic Positioning Turn Over: accomplished A side legend printing and transported to turn over, servo drive CCD to detect registration mark on B side for legend printing.

Clipper Flattening: substrate is deformed after various processing, clipper pulls to extend bilateral sides flattening while turn over to facilitate CCD registering, especially for thin film outstanding efficiency

Product detail pictures:

Related Product Guide:

We have now sophisticated machines. Our solutions are exported to the USA, the UK and so on, enjoying a great reputation amid consumers for Factory made hot-sale Curing Machine Screen Printing - Fully Automatic Thin Sheets Solder Mask Printing Line – Xinjinghui , The product will supply to all over the world, such as: Greece, Albania, Slovenia, As an experienced group we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of our company is to build up a satisfactory memory to all customers, and establish a long term win-win business relationship. Choose us, we always wait for your appearance!

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!