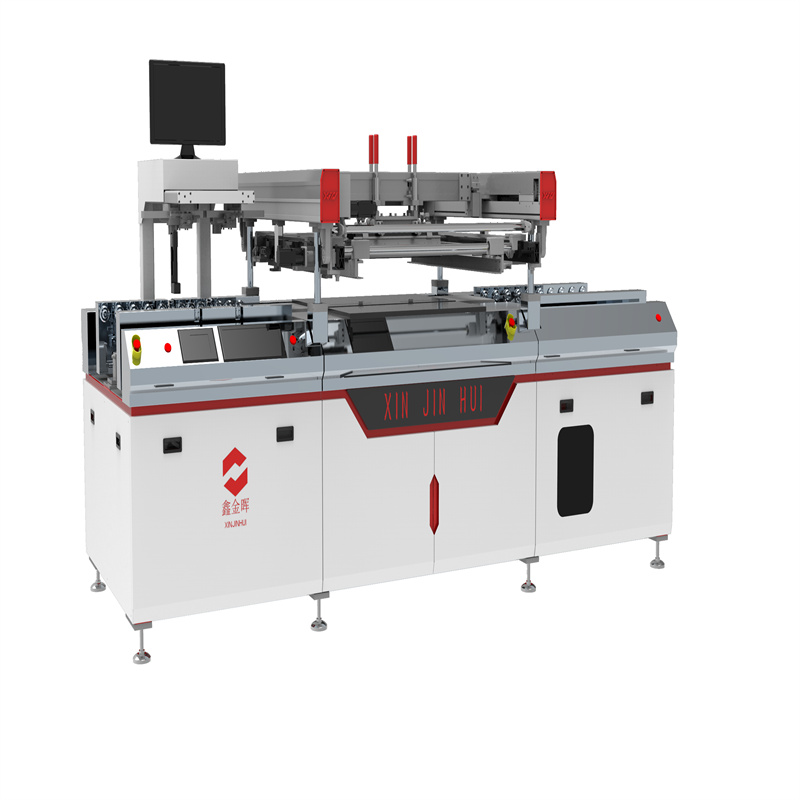

Factory wholesale Printed Circuit Board Machine - Intelligent Pressure Plug-via Screen Printer – Xinjinghui

Factory wholesale Printed Circuit Board Machine - Intelligent Pressure Plug-via Screen Printer – Xinjinghui Detail:

(1)Alignment method

1. The XXY alignment platform of the front monolithic section is equipped with 4 CCD lenses to immediately capture and feed back the target (or hole position) image on the substrate to the control system to compare the position. If the position is deviated, notify the X/Y/Y servo drive. The system starts up immediately, moves the alignment table (together with its upper substrate) to the exact position, and completes the alignment.

2. After the alignment is completed, the left and right conveyor table hooks fix the substrate on the conveyor table, and then bring the substrate to the printing section

(2) Plug-via section

1. The printing section adopts a stable top-level four-column screen printing head, equipped with a variety of uniquely designed precision movement and adjustment mechanisms, running smoothly and quietly, and positioning accurately:

— Printing head: reducer motor with encoder digital control, linear guide, single scraper and other 4 printing modes, manual scraper / ink-covering knife depth, rotation angle, tilt angle adjustment.

— Screen X/Y/Z fine-tuning: precise and smooth double-frame design, fine-tuning knob display for amplitude modulation, origin coordinate indication.

— CNC screen lift: Servo motor cooperates with precision ball screw and synchronous gear rack and four-column synchronous lift, CNC height setting (printing position/standby position/washing position).

2. The printing alignment mechanism adopts a servo-driven plate alignment system, which is adjusted by approaching the zero-gap alignment table, and the alignment accuracy reaches the um level.

(3) Discharge section

1. The discharge section is equipped with discharge conveying rollers to take the treadmill and bring it into the base plate, and bring it back to the conveyor.

2. The above design is based on the concept of “intelligent connection operation”, and with the horizontal conveyors in the front and rear sections, the input manpower can be greatly reduced and the production capacity can be increased.

(4)The self-locking function is set mechanically to ensure the stability and balance of the plug-VIA

(5)High-viscosity ink/resin can be filled with one knife

(6)Supporting pressurization system to maintain pressure balance, kg pressure 8-12kg

Product detail pictures:

Related Product Guide:

We attempt for excellence, support the customers, hopes to become the good cooperation team and dominator enterprise for staff, suppliers and shoppers, realizes worth share and continual marketing for Factory wholesale Printed Circuit Board Machine - Intelligent Pressure Plug-via Screen Printer – Xinjinghui , The product will supply to all over the world, such as: Bahrain, Poland, Albania, Please really feel free to send us your requirements and we'll respond to you asap. We have got a professional engineering group to serve for your just about every detailed needs. Cost-free samples could be sent for you personally to understand much more information. In an effort to meet your requires, please really feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd items. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is actually our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.