What comes here is the application of tunnel furnaces and energy-saving smart manufacturing strategies in the PCB circuit board production and manufacturing process.

PCB circuit board is a high-energy-consuming industry. The electricity consumed alone is a huge cost. At the same time, under the high-pressure impact of national and even global environmental protection and low-carbon policies, energy-saving intelligent manufacturing has enabled PCB companies to maintain market competitiveness and price advantages. The key link in this issue is the application and energy-saving smart manufacturing strategies in the PCB circuit board production and manufacturing process.

1. Application of tunnel furnace in PCB manufacturing industry

The tunnel furnace is mainly used in the drying process of PCB. At the same time, based on the characteristics of continuous automation and large batches of the tunnel furnace, it is especially suitable for high-volume drying conditions, such as: PCB circuit board solder mask (solder mask) ink screen printing pre-baking , PCB text printing, screen printing, baking, stress relief, etc.

Faced with different PCB circuit board size, thickness, weight, single or double-sided, number of layers, drying temperature, time and other process requirements, different tunnel ovens need to be selected to achieve better baking effects.

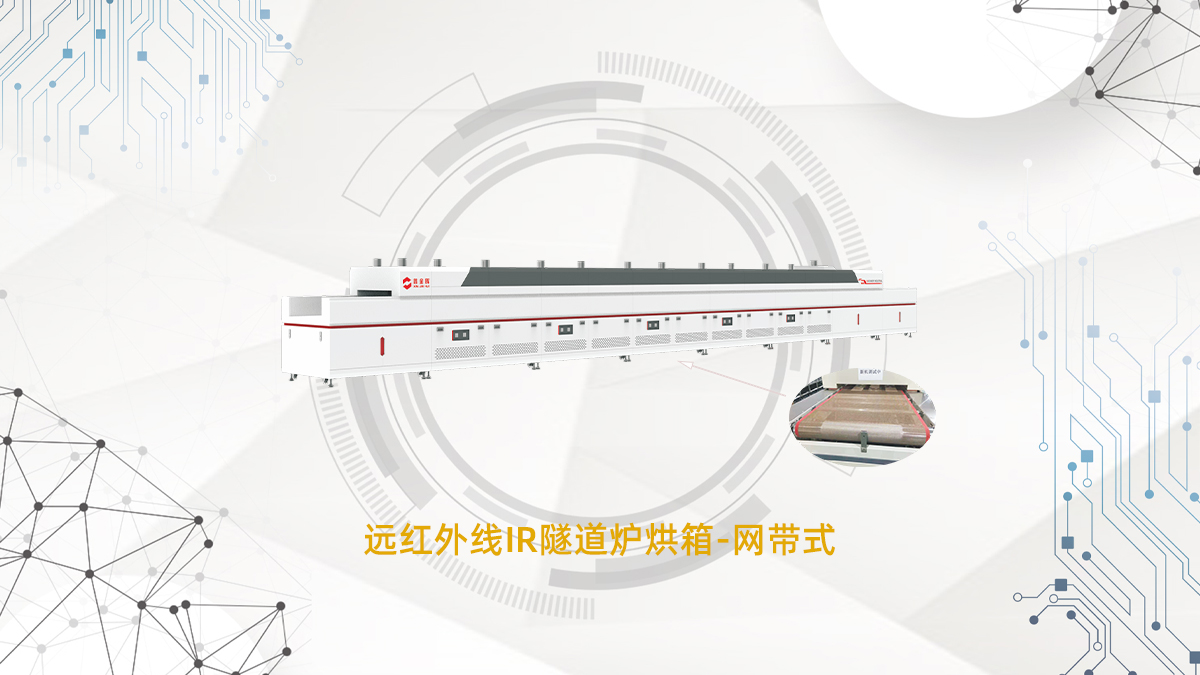

At present, special tunnel ovens for PCB circuit boards mainly use high-speed hot air circulation and IR far-infrared tunnel ovens. Suspended tunnel ovens, flip-type tunnel ovens, and side-clip/side-hug tunnel dryers can be selected for different working conditions. Line, rack-type tunnel furnace, mesh-belt tunnel furnace, roller tunnel, U-shaped double-sided far infrared IR tunnel furnace, etc. According to the baking and drying process conditions of PCB manufacturers, Jiangxi Xinjinhui Intelligent Technology Co., Ltd. can provide customers with on-site inspections of customer working conditions, tailor-made drying solutions, and help customers achieve economic benefits beyond expectations.

2. PCB circuit board energy-saving and intelligent manufacturing strategy

For PCB manufacturers, energy saving and smart manufacturing upgrades have always been one of the hot topics. Among them, the drying process, as one of the high energy consumption processes, has always been one of the core objects of energy saving transformation. For this reason, the energy saving of tunnel furnaces The process of globalization is imminent. As a representative brand of energy-saving tunnel furnaces in the PCB industry, Xinjinhui has established Shenzhen Xinjinhui Energy Saving Technology Co., Ltd., Dongguan Pengli Energy Saving Equipment Co., Ltd., and Jiangxi Xinjinhui Intelligent Technology Co., Ltd. since its establishment in 2003. , has obtained more than 160 patented technologies, has completely independent research and development, design, production and service capabilities, and is the main supplier of tunnel furnaces for more than 20 listed PCB group companies. Among them, the third-generation energy-saving tunnel furnace newly launched in 2023, compared with the first The generation energy saving exceeds 55%, and it is the only company in the industry whose plate spacing exceeds 15mm. The current mainstream tunnel oven oven plate spacing in the market is basically between 18 and 25.4mm.

3. Xin Jinhui, the representative brand of tunnel furnace manufacturers

By replacing the original traditional tunnel furnace and other drying equipment with the Xinjinhui energy-saving tunnel furnace, the energy-saving efficiency of the drying process can be greatly improved, and automated drying production can be realized. It can be automatically connected with other processes to achieve intelligent manufacturing.

Xin Jinhui’s energy-saving tunnel furnace has performed well in the application of PCB printed circuit boards, providing strong support for the PCB industry to achieve energy conservation and carbon reduction goals. It can provide customized services according to customer needs, fully utilize the equipment performance, and help customers reduce costs. It is efficient and has a rich product line that can adapt to various process conditions of customers. Welcome to contact us for more detailed information.

Post time: Aug-24-2024