In the production of PCB circuit boards, as a necessary high-efficiency and energy-saving equipment for the automated baking process, it has a significant impact on the final quality and reliability of PCB, as well as production efficiency and cost control. Faced with the high energy consumption and market competition of the PCB industry In the face of dual pressures and crises, we continue to develop and innovate, and launch a new generation of energy-saving products to help PCB manufacturers overcome the difficulties of saving power, reducing consumption, improving quality, and increasing efficiency.

2. A breakthrough tunnel furnace solution that saves energy and reduces costs in the text post-baking process for PCB manufacturers

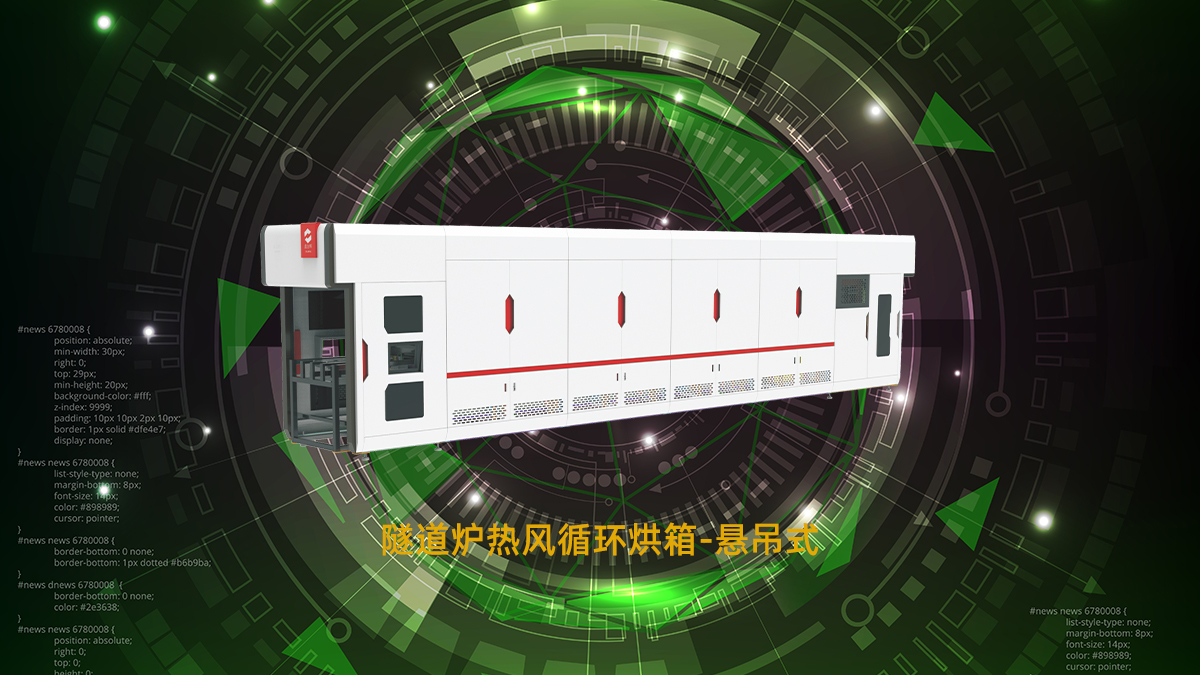

The advent of Xinjinhui’s third-generation energy-saving PCB tunnel oven marks an important step in the transformation of PCB baking technology to high efficiency and energy saving. Compared with traditional tunnel ovens, Xinjinhui’s products have achieved technological breakthroughs and efficiency innovations in many aspects.

1. Unique self-developed clamping fixtures, internal structures, machinery, and conveyor system design and innovation

The new technology overcomes the common pain points of the traditional suspension conveying method, such as easy board falling; it replaces the traditional fiberglass rod and plug-in rack module, eliminating the previous problem of fiberglass rods and plug-in racks absorbing heat, resulting in wasted heat loss. Thermal efficiency is further improved and energy saving is effectively enhanced; at the same time, the hollow furnace structure avoids obstruction, the ventilation quality is better, the furnace temperature is more balanced and even, and the baking speed is faster; and based on this, maintenance is more convenient and faster, reducing working hours. Waste, save maintenance costs, and improve maintenance efficiency.

2. The plate spacing exceeds 15mm, and the overall energy saving is increased by 55%.

When the current industry mainstream is still 25.4mm, 19mm, and 18mm (Xinjinhui second generation) board spacing, Xinjinhui has launched the third generation 15mm PCB tunnel oven. Based on innovation and reform in each link, compared with the first generation energy saving Increased to 55%, and made its debut at the 2023 CPCA SHOW International Electronic Circuit (Shenzhen) Exhibition, winning the attention and praise of global PCB manufacturers, further solidifying Xinjinhui’s market position as the benchmark brand of global energy-saving tunnel furnaces in the field of industrial baking and curing .

3. Compared with the first generation tunnel furnace, the length is shortened by more than 40%, and the factory space is saved astonishingly.

For PCB manufacturers, Xinjinhui’s third-generation tunnel furnace drying line shows unparalleled advantages in terms of stability, energy saving, and space saving. Whether it is a new factory put into operation or an old factory renovated, it is amazing in the industry. level of economic benefits.

4. In terms of safety, everything is checked from mechanism design to intelligent alarms and automatic power outages.

The design of Xinjinhui Tunnel Oven fully considers fire risk prevention, and ensures the safety and reliability of the baking process through intelligent control systems and safety monitoring mechanisms.

3. Summary

On the basis of maintaining or even improving baking quality, energy consumption can be reduced by up to 55%. This will undoubtedly significantly increase production capacity for fast-paced, high-volume PCB production lines, and for PCB manufacturers facing huge pressure on energy costs. Generally speaking, using Xinjinhui’s baking equipment can significantly reduce production costs, while at the same time responding to national energy conservation and emission reduction policy requirements and achieving green production.

In addition, Xinjinhui provides customized solutions for various complex baking requirements that may be encountered in PCB production, and can adjust baking strategies according to different PCB types and production conditions to ensure optimal baking effects.

As a product in response to market demand and environmental protection trends, Xin Jinhui’s technology and products demonstrate the determination and actions of the PCB manufacturing industry in pursuing efficient production and environmental protection; the dual advantages of environmental protection and economic benefits also make Xin Jinhui’s energy-saving tunnel furnaces It has gained wide recognition in the market.

Facing the growing global demand for electronic products and increasingly higher environmental standards, Jiangxi Xinjinhui Intelligent Technology Co., Ltd., as a leading representative brand among tunnel furnace manufacturers, will continue to use its advanced PCB baking equipment , providing the industry with a solution that takes into account efficiency, energy saving and safety, leading the PCB manufacturing business to a greener and more efficient future.

Post time: Oct-11-2024