In the field of electronic manufacturing, the production process of printed circuit boards (PCBs) is very complex and requires multiple links to complete. Among them, the PCB circuit board solder mask screen printing pre-baking and text screen printing post-baking, and drying production line are key links, which can improve the production efficiency and quality of PCB. This article will give you an in-depth introduction to the advantages and application scenarios of the production line, help you better understand the PCB screen printing drying process, and show you the performance of excellent equipment.

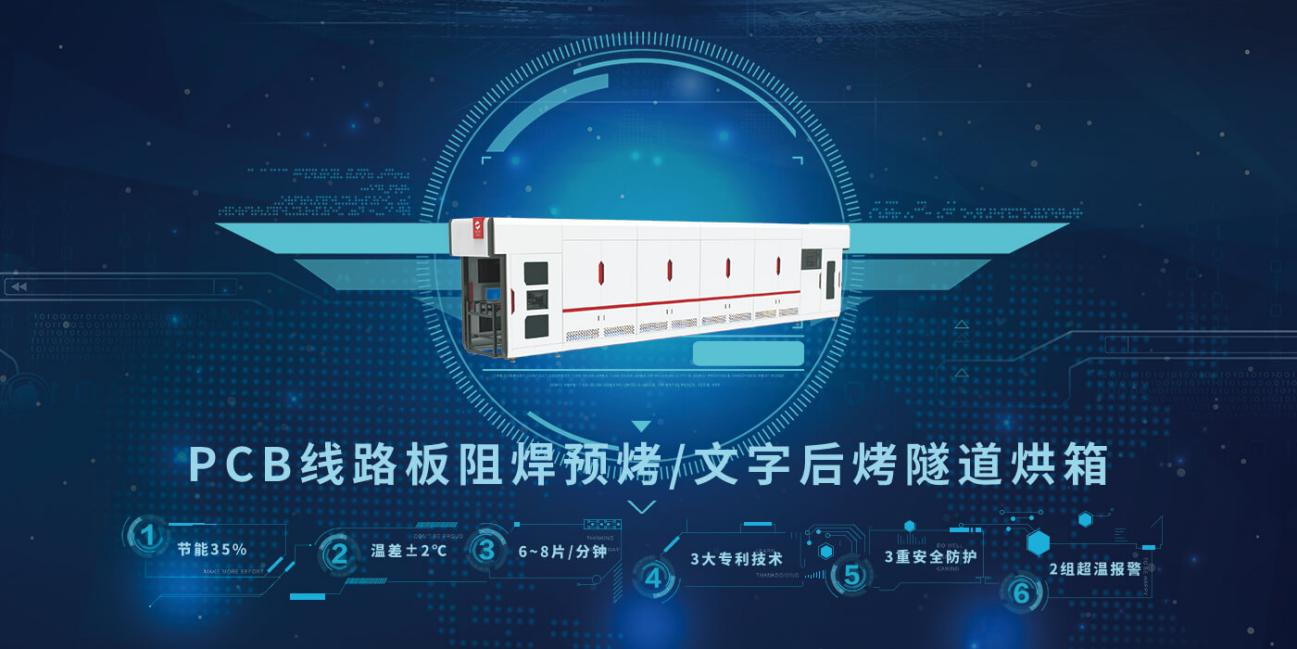

PCB circuit board solder mask pre-baking, text post-baking, and tunnel oven drying production lines adopt advanced conveying systems, heating systems, air transport systems, thermal insulation and other systems. It is an efficient and automated energy-saving equipment with the following characteristics:

1. High efficiency: This production line can achieve continuous production, greatly improving the production efficiency of PCB.

2. Automation: The solder mask text screen printing oven tunnel oven drying production line adopts automated control technology to reduce manual operations and improve production quality and efficiency.

3. Multi-function: This production line can be applied to PCBs of different types and specifications to meet the production needs of a variety of electronic products.

4. High quality: By strictly controlling temperature and time, this production line can ensure the excellent quality of the solder mask layer of the PCB and improve the reliability of the circuit board.

Xin Jinhui has the full range of R&D and production capabilities for PCB circuit board solder mask pre-baking and text post-baking screen printing oven tunnel oven drying lines. It can tailor tunnel oven oven equipment production lines according to the process requirements of different PCB boards and circuit board manufacturers. It has a number of Supported by patented software and hardware system technology, energy saving is up to 35%, top electrical hardware configuration, PLC temperature acquisition, automatic intelligent frequency conversion and frequency modulation control temperature, combined with high-speed circulating hot air and patented heating air transport system to achieve uniform baking and ensure the pcb screen printing drying effect It is good and fast, efficient, saves time and energy, and also has 3 sets of fire safety functions and 2 sets of safety alarms to ensure stable operation 24 hours a day.

In short, the PCB circuit board solder mask pre-baking and text post-baking screen printing oven tunnel oven drying production line is an indispensable production tool in the PCB production process. It has the characteristics of high efficiency, automation, multi-function and high quality, which can improve the production efficiency and quality of PCB and meet the production needs of different electronic products. In the future, with the continuous advancement of technology, Xinjinhui will continue to upgrade the energy-saving level and intelligent automation experience of tunnel oven equipment, helping PCB manufacturers reduce costs and increase efficiency, improve process efficiency, and enhance market competitiveness.

Post time: Apr-07-2024