On December 8, 2023, the “PCB Enterprise Environmental Protection and Work Safety Forum” was jointly organized by the Guangdong Circuit Board Industry Association (GPCA)/Shenzhen Circuit Board Industry Association (SPCA), Taiwan Circuit Board Association (TPCA) and Huawei CSR for many consecutive years. 》The conference event was grandly opened at Shenzhen Haoyue Grand Skylight International Hotel, providing a platform for experience and technology exchange for energy-saving, environmentally friendly production and safe manufacturing in the PCB industry. Through sharing and discussion together, it brought new inspiration, guidance and vitality to the development of the industry.

Jiangxi Intelligent Technology Co., Ltd. is the leader in the PCB industry in intelligent plugging machines, screen printing machines, energy-saving ovens and fully automatic plugging and screen printing drying production lines. Chairman Zhong Ruiming is honored to be solemnly invited by the organizer to participate in “PCB Enterprise Environmental Protection and Industrial Safety Forum” meeting, and delivered an important speech, “A breakthrough in energy saving and cost reduction in the PCB industry – Tunnel Furnace: Innovation and Application of Energy Saving and Energy Storage Technology”

The topics of this speech by Xin Jinhui Chairman Zhong Ruiming include an introduction to the development and upgrade of tunnel furnaces from the first generation to the third generation, sharing of the characteristics of the third generation PCB text post-baking, preview of new tunnel furnace products and future development plans; also There are many breakthrough new technologies and equipment such as dual running tables, intelligent pressure ink resin plugging machines, and good news that shocked the PCB industry.

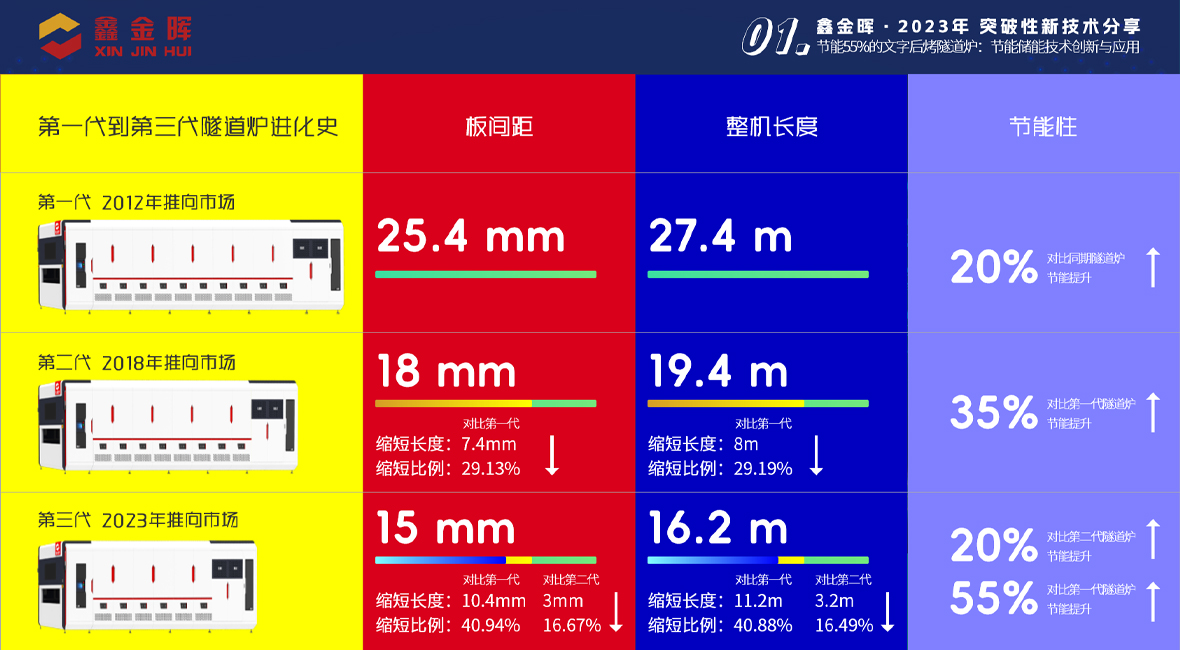

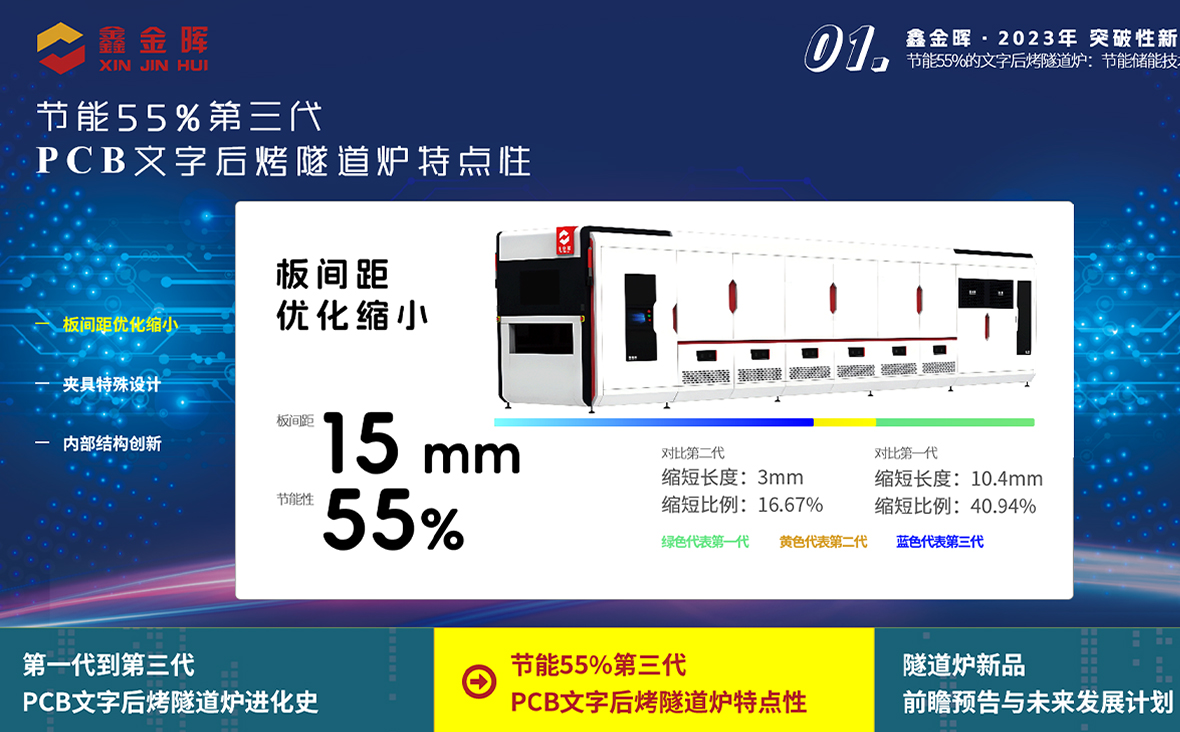

During the meeting, Xin Jinhui Chairman Zhong Ruiming vividly presented the evolution of tunnel furnaces to the audience through a data indicator comparison chart. Among them, the first generation of tunnel furnaces is more than 20% energy-saving compared to the same period of equipment. ; The second generation tunnel furnace has absorbed the successful experience and market feedback of the first generation. After 6 years of painstaking research and development, technological innovation, and quality improvement, it has reached the pinnacle of the industry once it was launched on the market in 2018, saving 35% energy compared to the first generation. , significantly ahead of the equipment of the same period, and as of 2023, it is still at the forefront of the industry; the third generation PCB text post oven can be said to be an epoch-making energy-saving tunnel drying equipment, with energy saving increased to 55%, and the board spacing exceeding 15mm. Under the same conditions of production speed, temperature and time, while saving huge amounts of power, the baking area is shortened by as much as 40.94%. Compared with the first generation machine, it is 11.2 meters shorter. In an era where every inch of land is precious, it saves valuable space for customers. resources, it perfectly solves the space accommodation problem of replacing equipment for old factory renovations, and its overwhelming energy-saving advantages also make it the best choice for new factory procurement.

As one of Xinjinhui’s blockbuster technologies in 2023, the third-generation PCB text post-baking tunnel oven that saves 55% of energy has stunning performance and has won the recognition and praise of all PCB professionals, and its energy-saving principles and expressed deep interest in technology.

Then Chairman Xin Jinhui Zhong Ruiming continued to announce two good news to everyone, previewing a 100% safe revolutionary new tunnel furnace, which changed the traditional heating method of using heating elements and solved the risk of fire in drying equipment from the source. Hidden danger; secondly, any customer who purchases Xinjinhui tunnel furnace can install energy storage equipment later.

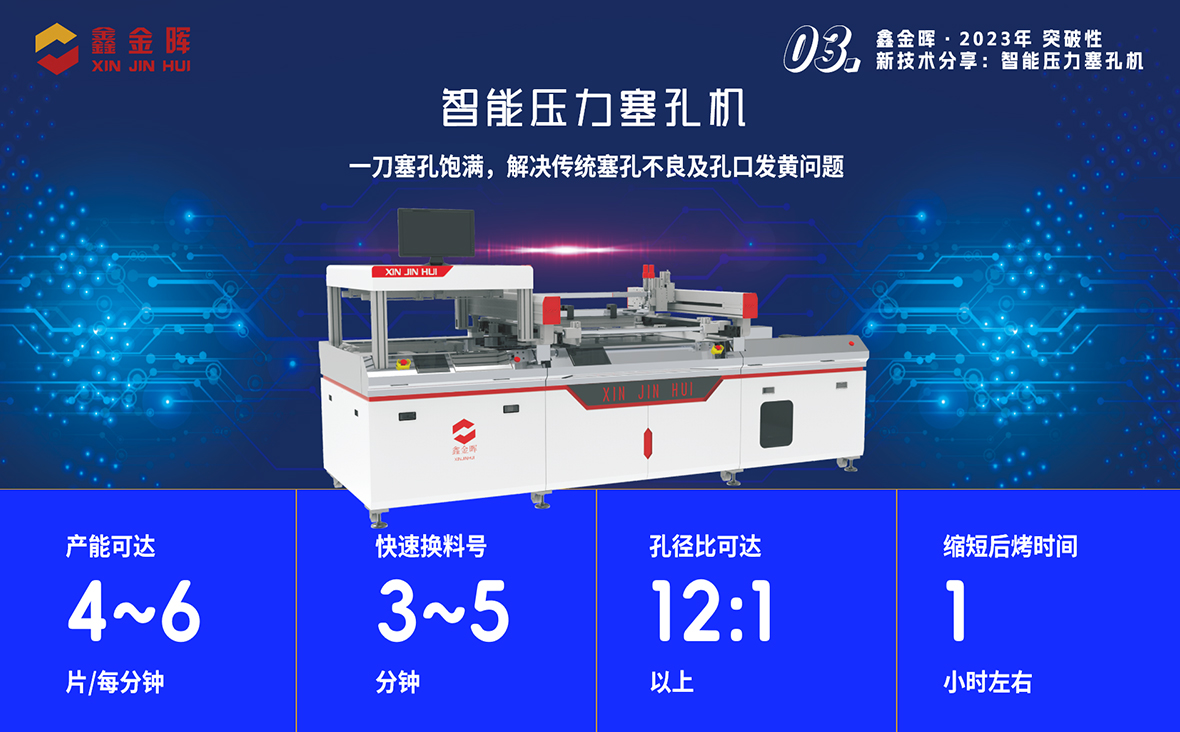

Next, Zhong Ruiming, chairman of Xinjinhui, introduced to everyone one by one the dual-running machine with a production capacity exceeding 2 to 3 pieces per minute; the fully automatic intelligent pressure plugging screen printing machine that solves problems such as poor traditional plugging and golden holes.

This “PCB Enterprise Environmental Protection and Work Safety Forum” gathered many experts and big names in the PCB industry. In addition to Xin Jinhui Expert Chairman Zhong Ruiming, he brought “A breakthrough in energy saving and cost reduction in the PCB industry – Tunnel Furnace: Innovation in Energy Saving and Energy Storage Technology” In addition to the wonderful speeches of Huawei Technology CSR expert Lin Song, Shennan Circuit EHS expert Guo Tao, Jingjin Electronics Marketing Director Wang Kao, Huatong Computer EHS expert Cheng Xianyou, Shengyi Electronics EHS expert Zhan Fengyue, Dong Liu Shouwei, an expert on environmental protection and safety, and Liang Yuanhui, director of Eton Electronic Safety Management Department, etc., all delivered important speeches that were conducive to the environmental protection, energy saving and safety development of PCB industry production.

At the meeting, there was also an exchange and interaction session to share experiences with each other, inspire corporate innovation, and open up new ideas and new ways for safety, environmental protection, energy conservation and emission reduction. With the rapid development of the PCB industry, the development of energy-saving and environmentally friendly process technology has become an inevitable trend. , Xin Jinhui will keep in mind its mission of being a leading enterprise in the manufacturing intelligent industry, practice its purpose of creating value for customers, always adhere to core technology invention and creation, drive productivity through science and technology, and empower China’s PCB industry to maintain a good, positive and healthy rapid development. develop.

Post time: Mar-13-2024