In the electronics manufacturing industry, circuit board ink plugging machines and drying are key process links in PCB board production. They play an important role in ensuring the quality of PCB boards and improving production efficiency. Remind PCB board manufacturers that the equipment of each manufacturer has different focuses and characteristics. If the matching is not good, it may cause adverse effects. Next, Xin Jinhui will analyze to you the secret of matching the PCB ink plugging machine and the tunnel furnace, and how to help PCB Manufacturers achieve doubling of process efficiency.

PCB circuit board ink plugging is an important step in the printing process. Its purpose is to ensure the sealing of the holes to provide good insulation and stability. Tunnel drying is an important process based on this. It solidifies the ink through high-temperature baking to further enhance the sealing of the holes.

During the tunnel oven drying process, the PCB circuit board ink plug holes can effectively prevent moisture from entering, thereby protecting the circuit board from moisture damage. At the same time, the good sealing of the ink plug hole also ensures the temperature stability inside the tunnel, making the drying process more uniform and efficient. Therefore, the connection between ink plugging and tunnel drying can be said to be complementary and inseparable.

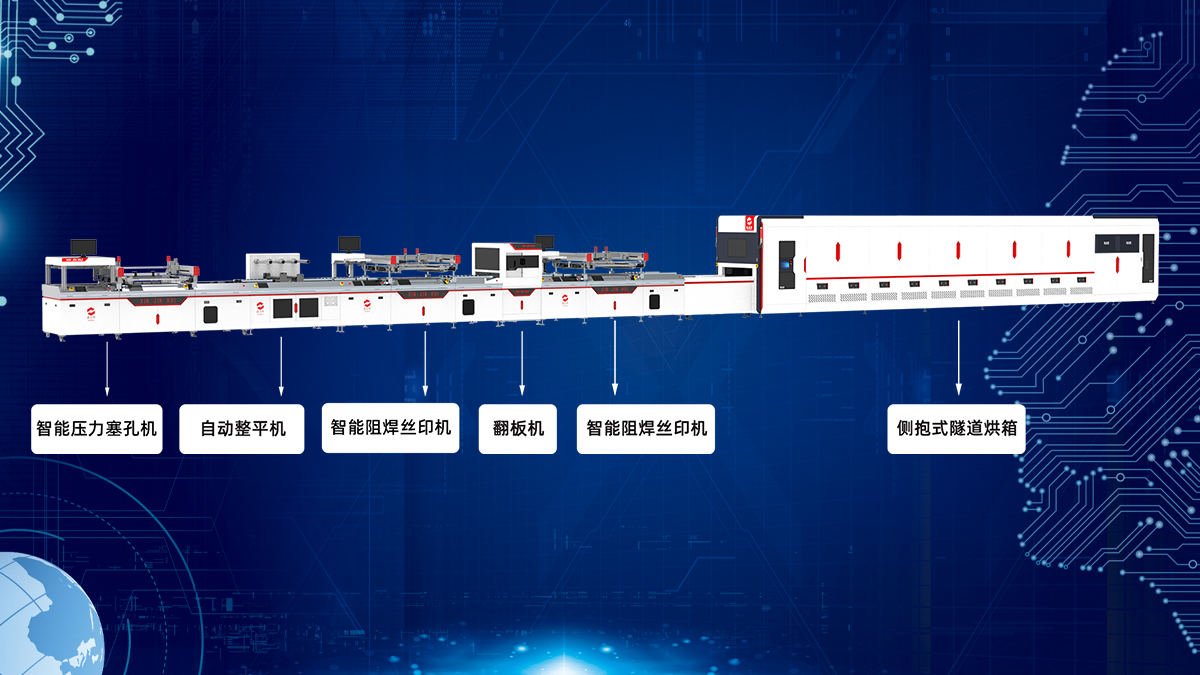

In order to further improve production efficiency and quality, many manufacturing companies have begun to introduce intelligent automation technology for transformation. For example, automated production lines can automatically complete processes such as PCB ink plugging and drying, reducing manual intervention and improving production efficiency. At the same time, the intelligent control system can monitor the production process in real time, accurately control the equipment, reduce energy consumption, and improve energy utilization efficiency.

Choosing energy-efficient equipment is also very important. For example, using high-efficiency drying equipment and intelligent control systems can reduce energy consumption. At the same time, through intelligent control systems, linkage between equipment is realized to further improve energy utilization efficiency. For example, the drying equipment and cooling equipment are linked together to automatically adjust the drying time and cooling time according to the temperature, thus saving energy.

Traditional PCB ink plugging machines often have insufficient plug holes due to problems such as insufficient pressure and insufficient accuracy, and even need to repeatedly plug holes. Secondly, in order to solve the problem of insufficient plug holes, the method of diluting the ink concentration is used in subsequent drying. Drying has higher requirements on drying temperature and time. At the same time, the shrinkage force generated during baking is too large, which can easily lead to voids, thinning of the ink at the orifice, and yellowing of the edges, which is the so-called golden hole phenomenon, which is very important for PCB. The quality of PCB is extremely risky, so this result is generally not accepted in application fields with higher PCB quality.

As a powerful manufacturer specializing in the technology research and development of automated production equipment for PCB plugging, PCB solder mask screen printing, and PCB screen printing drying processes, Xinjinhui has specially customized and developed an intelligent pressure plugging machine to address such pain points, which is different from traditional PCB ink plugging. Machine, self-developed boosting system, kilogram air pressure can reach 6-8KG, combined with self-locking mechanism and four-column power lifting system to ensure accurate and stable balance. The plug hole is full with one knife, eliminating the need for repeated operations and scrap board rework, comprehensively improving efficiency and increasing production capacity At the same time, all kinds of losses and waste are greatly reduced; because the use of Xinjinhui intelligent fully automatic pcb ink plugging machine can achieve the ideal plugging effect, the baking temperature in the subsequent drying stage can be higher, thus saving the baking time by 1 ~2 hours, comprehensively improving the comprehensive benefits of the entire process, and Xinjinhui’s energy saving is as high as 35%, which is industry-leading. It can save a lot of power costs for enterprises, relieve energy consumption pressure for PCB manufacturers, and provide a basis for environmental protection level assessment. Provide powerful assistance.

In short, PCB circuit board ink plug holes and tunnel drying are closely connected and are key process links in PCB board production. By introducing suppliers of PCB-specific intelligent automation and energy-saving equipment like Xin Jinhui, we can choose equipment with high energy efficiency, high degree of intelligent automation, reduce manpower dependence, optimize the spatial layout of the production line, strengthen production management and expand the market, etc. This drives PCB manufacturers to achieve high-efficiency and high-quality production goals, thereby maintaining their dominant position in the market.

Post time: Mar-18-2024