In the process of automated production of PCB boards and SMT boards, the process flow is cumbersome and complex. It is particularly critical to keep production smooth, which is equivalent to improving efficiency and reducing costs. For this reason, a series of SMT boards, PCB circuit boards, and intelligent fully automatic auxiliary equipment have been derived to solve the problem. During the production process, there are problems such as material congestion and shortage, and manual instability and unsmoothness. In this issue, we bring you a pcb static horizontal cooling lifting temporary storage machine, explaining the working principle and function of a new generation of pcb temporary storage machines, and a one-stop circuit solution PCB board buffering, cooling, sheet transportation and other requirements required for multiple processes in the board factory.

1. The role of SMT board and PCB board automated cache temporary storage machine equipment

SMT board and PCB board automatic cache and temporary storage machines can play the role of transfer, buffering, cooling, and plate transportation for each production process during the automated production of PCB circuit boards. Through the automatic cache and temporary storage machine equipment, Effectively optimize process steps with low labor dependence, save labor costs, shorten waiting time, ensure smooth and controllable production rhythm, effectively avoid production congestion, avoid production stagnation due to material shortages and other problems, as well as problems caused by untimely processing Phenomena such as plate collision and damage can ensure stable and reliable operation while greatly improving production efficiency.

2. SMT/PCB board automated cache temporary storage pain points and traditional equipment disadvantages

1. In the past, SMT boards and PCB boards did not use automatic cache machines, mainly because they were worried that the equipment would be scratched and scratched on the board surface during operation, causing indentations and collision damage.

2. Conventional cache storage machines on the market have some limitations, such as: insufficient temporary storage quantity and resting time, large equipment size, and inconvenient wiring automation. Secondly, the operation mode design is not reasonable enough, causing the panels to be transported during the transportation process. Problems such as curling may occur, affecting product quality. For some large-sized and heavy-weight PCB circuit boards, components such as steering gears may be overburdened, affecting the life of the equipment and causing higher costs.

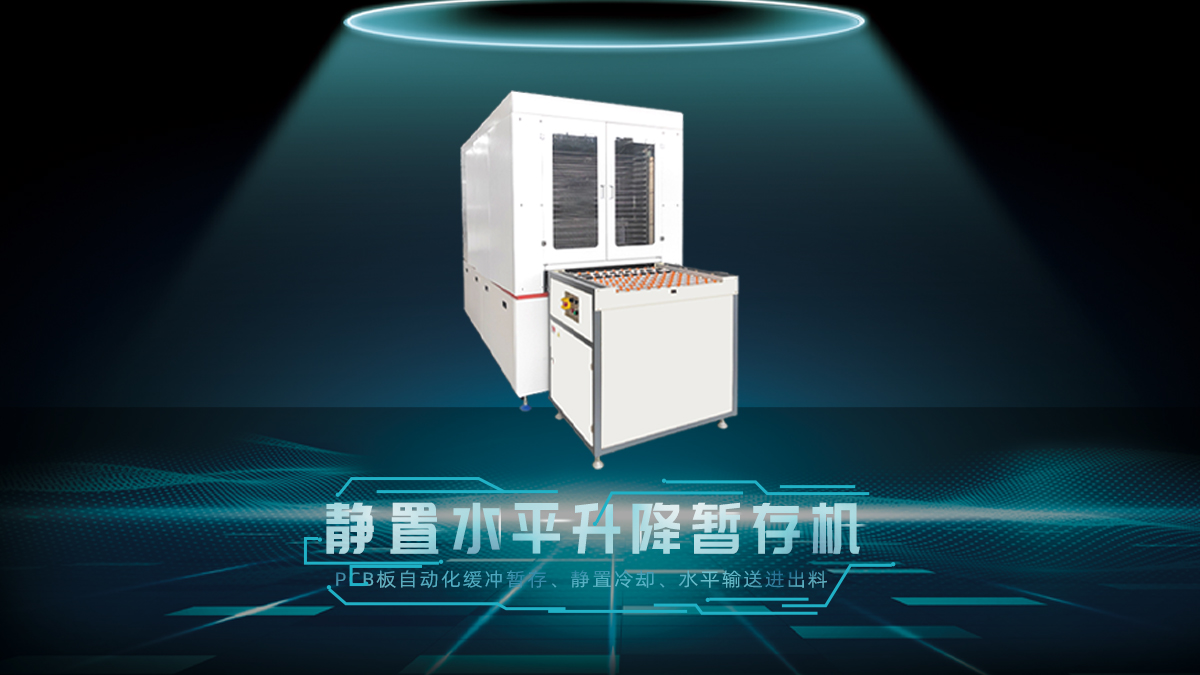

3. The working principle and introduction of the new generation of fully automatic cache and temporary storage machine – static horizontal lifting and cooling temporary storage machine

As a professional manufacturer of intelligent automation equipment in the PCB industry for 20 years, Xin Jinhui’s new generation of static horizontal lifting cooling temporary storage machine is based on a large number of PCB circuit board customer cooperation experience and customer demand feedback, from the perspective of circuit board customer process, It is an innovative PCB cache cache device that is designed globally and innovatively. It cleverly solves the shortcomings of traditional cache machines, and can customize the number of layers and set the waiting time according to the actual situation of the customer.

The core difference between the static horizontal lifting cooling buffer machine and the traditional cache buffer machine is that the PCB board is transported smoothly in the horizontal direction, with A side entering and A side exiting, without the need to turn over the board to avoid contact between circuit boards, thus preventing A series of customers are worried about possible problems, but there is no need to worry about thin circuit boards. The entire process is placed horizontally and will not curl due to unevenness.

The design form based on the cyclic lift-type temporary storage makes the whole machine more compact and reasonable, does not waste excess space, covers a smaller area, has superior temporary storage quantity and resting time, and has a very high overall cost-effectiveness, and is more suitable for SMT/PCB board full-scale installation. Automatic line production.

Combined with some ingenious detailed designs, the panels can be protected as much as possible during the operation of the stationary horizontal lifting cooling storage machine, such as:

1. The conveyor roller uses a speed-regulating motor + a belt conveyor + a silicone roller, which has a buffering effect to prevent noise from the collision between the circuit board and the support rod, and at the same time prevents the circuit board from being damaged.

2. The input conveyor belt and the output conveyor belt adopt overall reinforced pallet racks, which have strong support and strong load-bearing capacity and can adapt to various plate phenomena.

3. The translation screw adopts a glass fiber rod covered with a small silicon ring, which is resistant to high temperatures and can prevent circuit board slippage and indentation.

The static horizontal lifting cooling temporary storage machine can be widely used in various PCB circuit board processes and has strong versatility, such as: static cooling function before and after exposure, white oil board defoaming and smoothing setting function, and can meet the needs of special boards after pre-baking. Baking and cooling function, etc.

The above introduces the working principle and function of Xin Jinhui’s newly launched static horizontal lifting cooling buffer machine, and comprehensively analyzes the needs and concerns of buffer storage, static cooling, and plate transportation in the fully automatic production process of PCB board customers. concerns, and solve the shortcomings of traditional temporary storage machines, provide strong support for another leap in automation level of PCB board manufacturers, reduce labor requirements and labor costs, ensure fully automatic, accurate, efficient and stable operation, and shorten production waiting or stagnation time. Avoid the influence of unstable factors such as manual errors, reduce production waste, and give full play to the value of automation. In addition, Xinjinhui can also provide intelligent fully automatic PCB circuit board text/, pressure or vacuum resin ink plugging machines, and solder mask pre-baking according to customer needs. / Text post-baking, infrared tunnel oven and all-in-one production connection non-standard customization services fully solve customers’ pain points and difficulties, give full play to the role of equipment solutions, and produce benefits beyond expectations.

Post time: Apr-23-2024