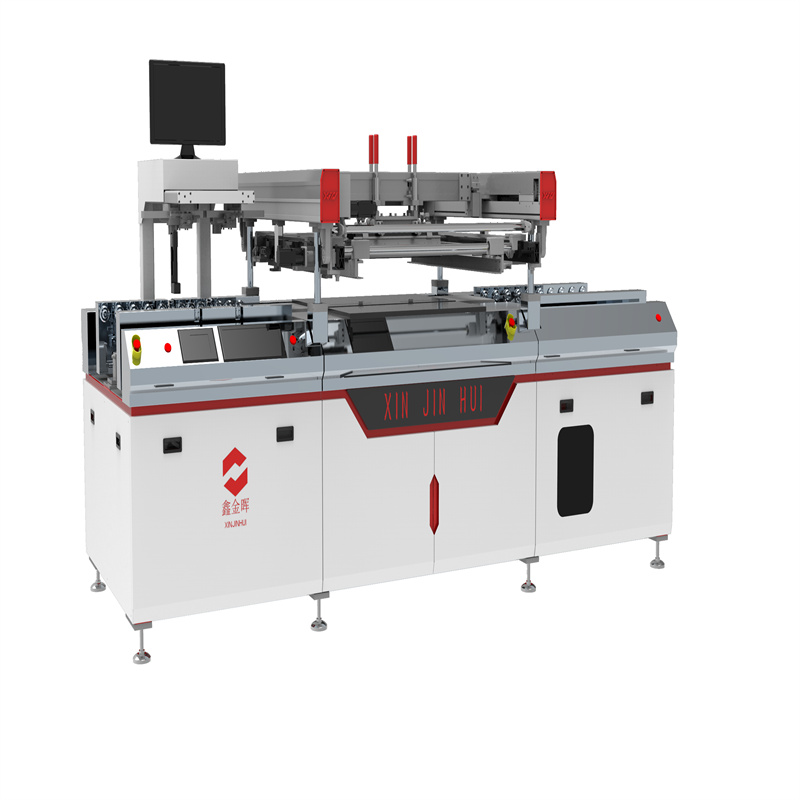

Quality Inspection for Cylindrical Silk Screen Printing Machine - Fully Automatic Thin Sheets Solder Mask Printing Line – Xinjinghui

Quality Inspection for Cylindrical Silk Screen Printing Machine - Fully Automatic Thin Sheets Solder Mask Printing Line – Xinjinghui Detail:

CCD alignment system is adopted, and the material number is switched in 3-5min

Compatible with the production of 0.4mm-3.0mm plates

The production capacity reaches 3-6pnl / min

Realize [digitalization], [parameterization] and [intelligence]

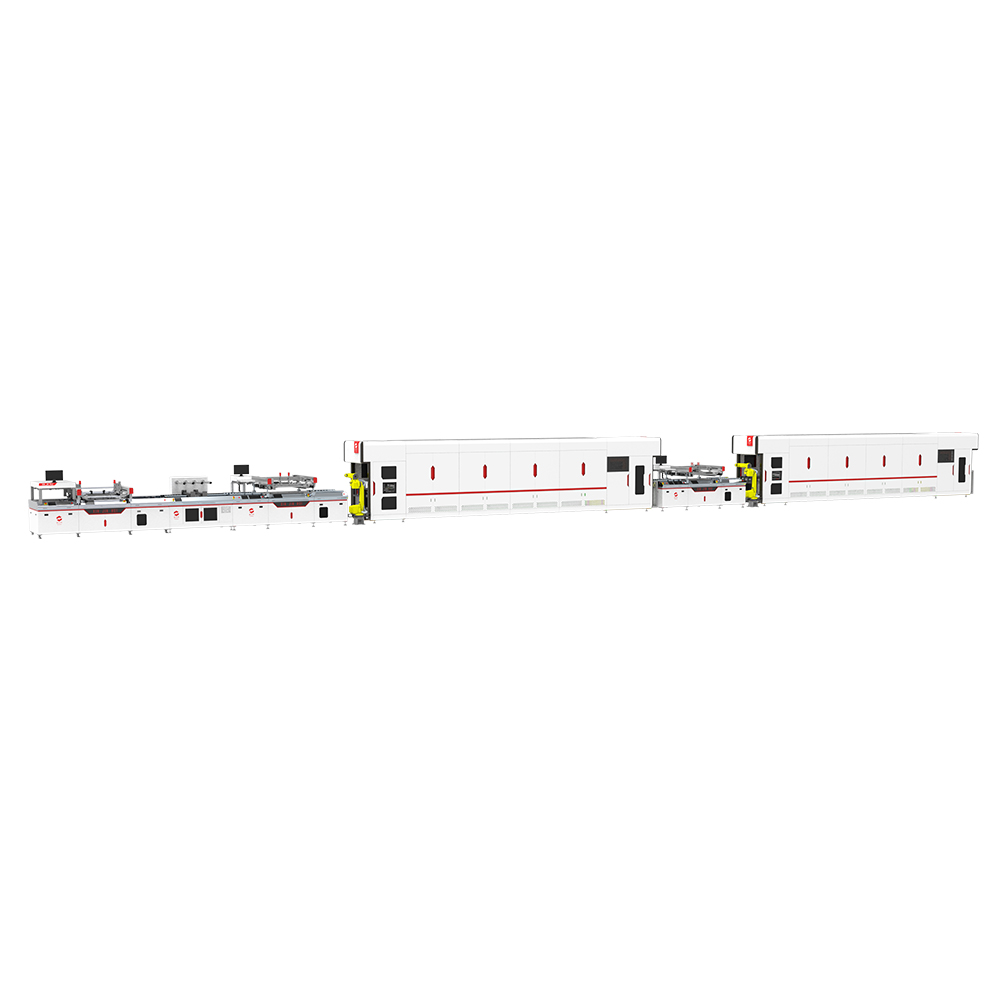

Manipulator loading and unloading to realize the whole line fully automatic

Visual Registration: 2 CCD cameras detect registration mark or hole on substrate rapidly, mathematically calculate position off-set amount providing to control system, X/Y servo transmission system drives registration table immediately to precise position.

Laser Point: CCD camera module is locked / unlocked by pneumatic control switch, fast displacement and manual fine adjusting front back / right left position, collocated with laser point projection for quick moving to target position.

Digital Control Screen Micro Adjustment: replace manual three-point micro adjustment, which is unable to adjust precisely obtaining the requested position, digitalized control compensation attains quick precise efficiency.

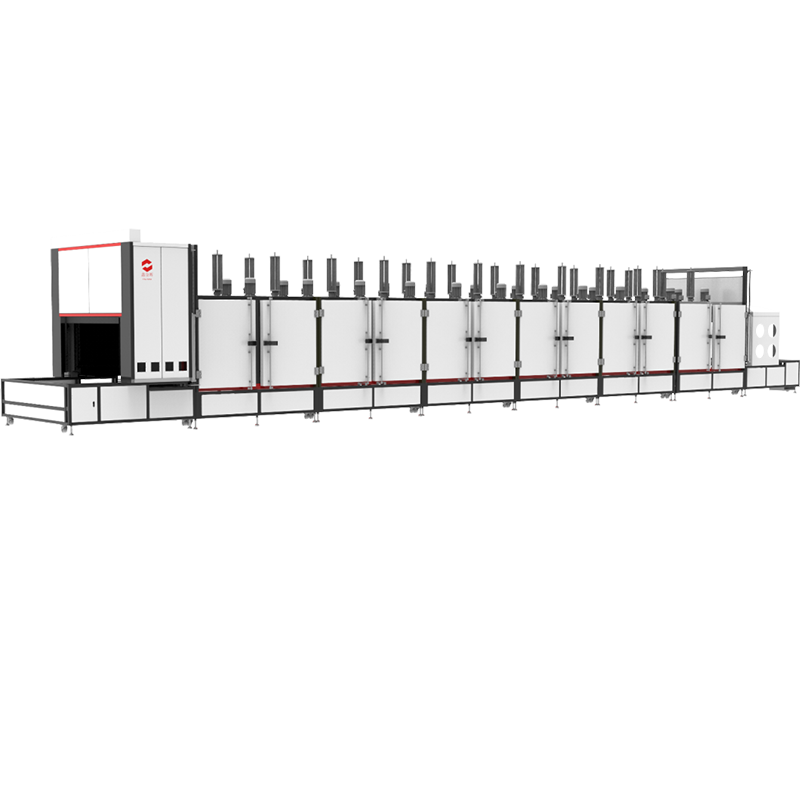

Buffer Stacker: when B side screen printer stops for screen cleaning, A side incoming after printing, temporary stack into buffer stacked to avoid influence production efficiency.

Automatic Positioning Turn Over: accomplished A side legend printing and transported to turn over, servo drive CCD to detect registration mark on B side for legend printing.

Clipper Flattening: substrate is deformed after various processing, clipper pulls to extend bilateral sides flattening while turn over to facilitate CCD registering, especially for thin film outstanding efficiency

Product detail pictures:

Related Product Guide:

Based on domestic market and expand overseas business is our development strategy for Quality Inspection for Cylindrical Silk Screen Printing Machine - Fully Automatic Thin Sheets Solder Mask Printing Line – Xinjinghui , The product will supply to all over the world, such as: Afghanistan, Tunisia, US, We have many years' experience in hair product production, and our strict QC Team and skilled workers will ensure that we give you high quality hair products with the high hair quality and workmanship. You will get successful business if you choose to cooperate with such a professional manufacturer. Welcome your order cooperation!

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.