Quality Inspection for Cylindrical Silk Screen Printing Machine - Intelligent Pressure Plug-via Screen Printer – Xinjinghui

Quality Inspection for Cylindrical Silk Screen Printing Machine - Intelligent Pressure Plug-via Screen Printer – Xinjinghui Detail:

(1)Alignment method

1. The XXY alignment platform of the front monolithic section is equipped with 4 CCD lenses to immediately capture and feed back the target (or hole position) image on the substrate to the control system to compare the position. If the position is deviated, notify the X/Y/Y servo drive. The system starts up immediately, moves the alignment table (together with its upper substrate) to the exact position, and completes the alignment.

2. After the alignment is completed, the left and right conveyor table hooks fix the substrate on the conveyor table, and then bring the substrate to the printing section

(2) Plug-via section

1. The printing section adopts a stable top-level four-column screen printing head, equipped with a variety of uniquely designed precision movement and adjustment mechanisms, running smoothly and quietly, and positioning accurately:

— Printing head: reducer motor with encoder digital control, linear guide, single scraper and other 4 printing modes, manual scraper / ink-covering knife depth, rotation angle, tilt angle adjustment.

— Screen X/Y/Z fine-tuning: precise and smooth double-frame design, fine-tuning knob display for amplitude modulation, origin coordinate indication.

— CNC screen lift: Servo motor cooperates with precision ball screw and synchronous gear rack and four-column synchronous lift, CNC height setting (printing position/standby position/washing position).

2. The printing alignment mechanism adopts a servo-driven plate alignment system, which is adjusted by approaching the zero-gap alignment table, and the alignment accuracy reaches the um level.

(3) Discharge section

1. The discharge section is equipped with discharge conveying rollers to take the treadmill and bring it into the base plate, and bring it back to the conveyor.

2. The above design is based on the concept of “intelligent connection operation”, and with the horizontal conveyors in the front and rear sections, the input manpower can be greatly reduced and the production capacity can be increased.

(4)The self-locking function is set mechanically to ensure the stability and balance of the plug-VIA

(5)High-viscosity ink/resin can be filled with one knife

(6)Supporting pressurization system to maintain pressure balance, kg pressure 8-12kg

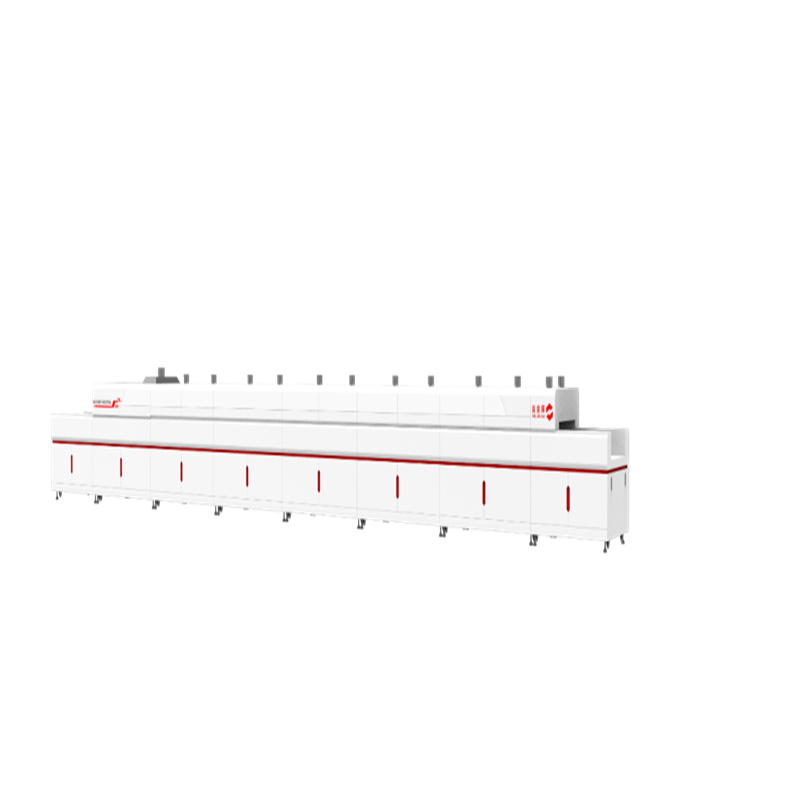

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of regard the market, regard the custom, regard the science and the theory of quality the basic, belief the very first and management the advanced for Quality Inspection for Cylindrical Silk Screen Printing Machine - Intelligent Pressure Plug-via Screen Printer – Xinjinghui , The product will supply to all over the world, such as: Victoria, Guatemala, Congo, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.