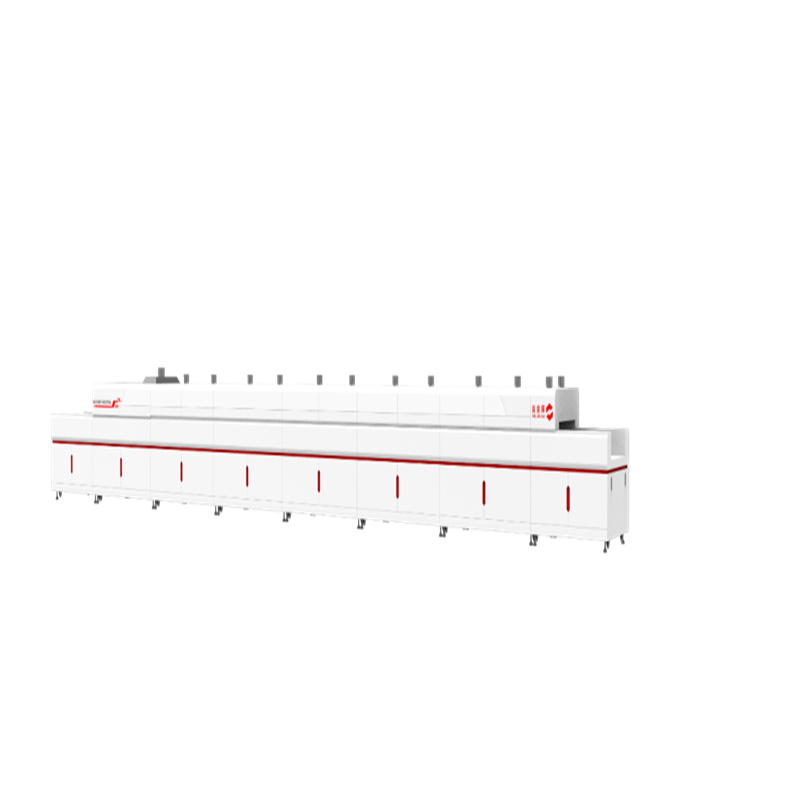

Short Lead Time for Manual Silk Screen Printing Machine - Fully Automatic Thin Sheets Solder Mask Printing Line – Xinjinghui

Short Lead Time for Manual Silk Screen Printing Machine - Fully Automatic Thin Sheets Solder Mask Printing Line – Xinjinghui Detail:

CCD alignment system is adopted, and the material number is switched in 3-5min

Compatible with the production of 0.4mm-3.0mm plates

The production capacity reaches 3-6pnl / min

Realize [digitalization], [parameterization] and [intelligence]

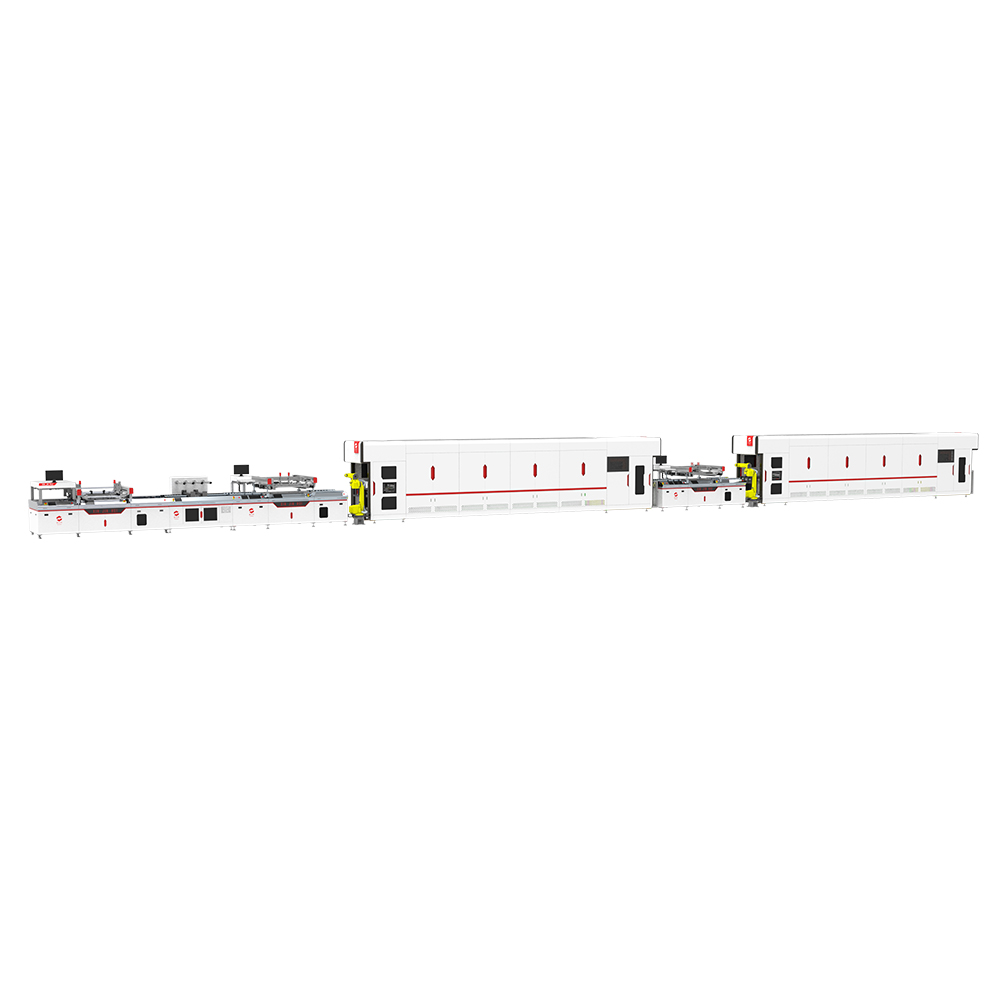

Manipulator loading and unloading to realize the whole line fully automatic

Visual Registration: 2 CCD cameras detect registration mark or hole on substrate rapidly, mathematically calculate position off-set amount providing to control system, X/Y servo transmission system drives registration table immediately to precise position.

Laser Point: CCD camera module is locked / unlocked by pneumatic control switch, fast displacement and manual fine adjusting front back / right left position, collocated with laser point projection for quick moving to target position.

Digital Control Screen Micro Adjustment: replace manual three-point micro adjustment, which is unable to adjust precisely obtaining the requested position, digitalized control compensation attains quick precise efficiency.

Buffer Stacker: when B side screen printer stops for screen cleaning, A side incoming after printing, temporary stack into buffer stacked to avoid influence production efficiency.

Automatic Positioning Turn Over: accomplished A side legend printing and transported to turn over, servo drive CCD to detect registration mark on B side for legend printing.

Clipper Flattening: substrate is deformed after various processing, clipper pulls to extend bilateral sides flattening while turn over to facilitate CCD registering, especially for thin film outstanding efficiency

Product detail pictures:

Related Product Guide:

Dependable good quality and very good credit score standing are our principles, which will help us at a good -ranking position. Adhering towards the tenet of quality initial, shopper supreme for Short Lead Time for Manual Silk Screen Printing Machine - Fully Automatic Thin Sheets Solder Mask Printing Line – Xinjinghui , The product will supply to all over the world, such as: Florida, Bahrain, Singapore, With the advanced workshop, professional design team and strict quality control system, based on mid- to high-end marked as our marketing positioning, our products are fast selling onto European and American markets with our own brands such as below Deniya, Qingsiya and Yisilanya.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.